03

Aug

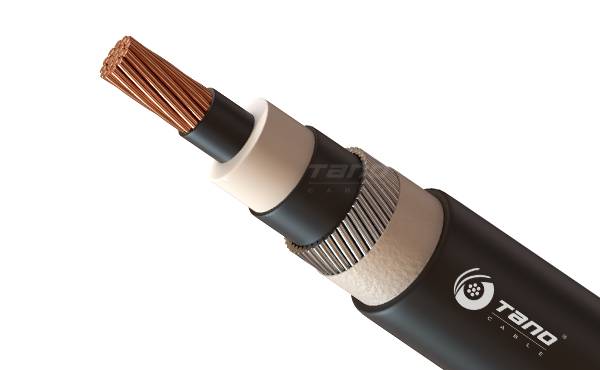

XLPE cable benefits

Share:

Cross-linked polyethylene (PEX or XLPE) has been around for quite some time. The first cross-linking methods emerged in the 1930s and practices have continued to evolve since, with other processes being developed throughout the years. Cross-linking is a very intricate process. XLPE raw material powder is formed and processed into sturdy, durable end products, usually formed into cylindrical shapes that can be used for electric industry.

There are many benefits to cross-linked polyethylene. Some include:

. Works with a variety of voltage ranges 600V to 35kV

. Provides mechanical protection

. Can withstand extreme pressure

. Resists underground damage

. Weather-resistant

. Thermal resistance

. Permits high conductor operating temperatures

. Reduces short circuit and overload levels

. Is more cost effective than traditional solutions

. Flexible

. Moisture resistant

Cross-linked polyethylene can be useful in the electric industry. At present, most of the high-voltage cables have been used for cross-linked polyethylene insulated cross-linked cables, The most commonly used material is cross-linked polyethylene (XLPE). Cross-linked cable is short for cross-linked polyethylene (XLPE) insulated cable. Cross-linked cables are suitable for transmission and distribution lines with power frequency AC voltage of 500KV and below.

Processing engineering is the process of using polyethylene (PE) material with linear molecular structure through a specific processing method to form a cross-linked polyethylene with a body-shaped network split line structure. The long-term allowable working temperature is increased from 70°C to 90°C (or higher), and the short-circuit allowable temperature is mainly increased from 140°C to 250°C (or higher). While maintaining its original excellent electrical performance, it has greatly improved Actual performance.

XLPE cable characteristics

The aging life of cable insulation material mainly depends on its thermal aging life. It is determined by the speed of thermal oxygen oxidation, thermal cracking, thermal oxidative cracking, polycondensation and other chemical reactions that occur in the insulating material under heat. Therefore, the insulating material The thermal aging life of the cable directly affects the service life of the cable. According to the chemical reaction kinetics derivation and the artificial accelerated thermal aging test (20-30 years), the long-term allowable working temperature of the irradiated cross-linked cable is:

1. If the power cable 0.6/1KV(LV Cable) is deduced according to the rated working temperature of 105 degrees, its thermal aging life exceeds 60 years.

If deduced according to the rated operating temperature of 90 degrees, its thermal aging life exceeds 100 years.

When overhead insulated cables are laid in the open air, the environmental and radiation resistance of insulating materials is more important. Irradiation cross-linked insulating materials have to undergo irradiation processing, and they have good radiation resistance. The radiation dose applied in the cross-linking production process leaves a large safety margin from the destruction dose.

Between XLPE and PVC as used in cable insulation

XLPE is suitable for voltage ranges from low to extra high voltage, surpassing other insulation materials such as PVC, Ethylene Propylene Rubber (EPR) and silicone rubbers. Cross-linking the polyethylene also enhances the chemical and oil resistance at elevated temperatures and makes it suitable for use as a Low Smoke Zero Halogen material.

The mechanical properties of the XLPE are superior to many other insulations, offering greater tensile strength, elongation and impact resistances. The addition of carbon black can be used to further enhance hot deformation and cut through resistance. The XLPE insulation will not melt or drip, even at the temperatures of soldering irons, and it has increased flow resistance and improved ageing characteristics.

Improved water-tree resistance is another benefit of XLPE insulation for LV cables and MV cables over PE insulations. Water treeing is a defect which is the result of imperfections in the insulation where fracture lines occur and grow in the direction of the electric field, increasing with electrical stress.

There are many benefits to cross-linked polyethylene. Some include:

. Works with a variety of voltage ranges 600V to 35kV

. Provides mechanical protection

. Can withstand extreme pressure

. Resists underground damage

. Weather-resistant

. Thermal resistance

. Permits high conductor operating temperatures

. Reduces short circuit and overload levels

. Is more cost effective than traditional solutions

. Flexible

. Moisture resistant

Cross-linked polyethylene can be useful in the electric industry. At present, most of the high-voltage cables have been used for cross-linked polyethylene insulated cross-linked cables, The most commonly used material is cross-linked polyethylene (XLPE). Cross-linked cable is short for cross-linked polyethylene (XLPE) insulated cable. Cross-linked cables are suitable for transmission and distribution lines with power frequency AC voltage of 500KV and below.

Processing engineering is the process of using polyethylene (PE) material with linear molecular structure through a specific processing method to form a cross-linked polyethylene with a body-shaped network split line structure. The long-term allowable working temperature is increased from 70°C to 90°C (or higher), and the short-circuit allowable temperature is mainly increased from 140°C to 250°C (or higher). While maintaining its original excellent electrical performance, it has greatly improved Actual performance.

XLPE cable characteristics

The aging life of cable insulation material mainly depends on its thermal aging life. It is determined by the speed of thermal oxygen oxidation, thermal cracking, thermal oxidative cracking, polycondensation and other chemical reactions that occur in the insulating material under heat. Therefore, the insulating material The thermal aging life of the cable directly affects the service life of the cable. According to the chemical reaction kinetics derivation and the artificial accelerated thermal aging test (20-30 years), the long-term allowable working temperature of the irradiated cross-linked cable is:

1. If the power cable 0.6/1KV(LV Cable) is deduced according to the rated working temperature of 105 degrees, its thermal aging life exceeds 60 years.

If deduced according to the rated operating temperature of 90 degrees, its thermal aging life exceeds 100 years.

When overhead insulated cables are laid in the open air, the environmental and radiation resistance of insulating materials is more important. Irradiation cross-linked insulating materials have to undergo irradiation processing, and they have good radiation resistance. The radiation dose applied in the cross-linking production process leaves a large safety margin from the destruction dose.

Between XLPE and PVC as used in cable insulation

XLPE is suitable for voltage ranges from low to extra high voltage, surpassing other insulation materials such as PVC, Ethylene Propylene Rubber (EPR) and silicone rubbers. Cross-linking the polyethylene also enhances the chemical and oil resistance at elevated temperatures and makes it suitable for use as a Low Smoke Zero Halogen material.

The mechanical properties of the XLPE are superior to many other insulations, offering greater tensile strength, elongation and impact resistances. The addition of carbon black can be used to further enhance hot deformation and cut through resistance. The XLPE insulation will not melt or drip, even at the temperatures of soldering irons, and it has increased flow resistance and improved ageing characteristics.

Improved water-tree resistance is another benefit of XLPE insulation for LV cables and MV cables over PE insulations. Water treeing is a defect which is the result of imperfections in the insulation where fracture lines occur and grow in the direction of the electric field, increasing with electrical stress.

Previous article:

Next article:

.jpg)

.jpg)