18

Mar

The hazards of unqualified wires and cables

Share:

Wires and cables are a large class of electrical products used to transmit power, transmit information, and achieve electromagnetic energy conversion. During the random inspection, a large number of unqualified products were found. These inferior products have buried many hidden dangers for the normal operation of the power system.

1. Mark unqualified wires and cables. Marking is the main way for wires and cables to identify the basic information of products. According to the standard, the main content of the mark is: product model, specification, standard number, factory name, place of origin, etc. within a certain mark interval. When the mark is unqualified, it will cause The construction personnel's identification errors may cause electrical accidents in serious cases.

2. Wires and cables with unqualified structural dimensions. The main problem of the structure size is the thickness of the sheath and the insulation thickness. When the sheath and insulation thickness of the cable are not up to the standard, the electric resistance strength of the wire and cable will be seriously reduced, resulting in the shortening of the service life of the wire and cable, and in severe cases, the wire and cable may be damaged. Breakdown, the insulation (sheath) layer fails to provide normal protection, resulting in electrical short circuits and fires.

3. Wire and cable with qualified tensile strength and elongation of sheathed insulation before aging. The unqualified tensile strength and elongation of the insulating sheath before aging directly greatly shorten the working life of the wire and cable, and during construction or in a long-time energized environment with high temperature, the insulator is easily broken, resulting in a live conductor Exposed, there is a risk of electric shock short-circuit. The main reason for its disqualification is the use of recycled materials to reduce product costs, and the second is small enterprises that are not qualified for production.

4. Wires with unqualified conductor resistance. Conductor resistance is mainly an important indicator for assessing whether the conductor materials and cross-sections of wires and cables meet. When the conductor resistance exceeds the standard, the loss when the current passes through the line is increased, and the heating of the wire and cable is aggravated. The main reason for the unqualified conductor resistance is to reduce the cost of the copper material, which accounts for 80% of the raw material cost. In order to reduce the cost, either reduce the cross-sectional area of the conductor or use recycled copper with excessive impurities, which causes serious conductor resistance of the wire and cable. Exceeding the standard, in addition to easy to cause fire during use, it will also accelerate the aging of the insulating layer covering the wire.

When you use TANO CABLE’s products, you don’t worry about the problems of cable. We pay attention to quality of cables and reputation. As a leading and professional manufacturer, we are committed to providing customers and partners with the best integrated cable and wire solutions to save manpower, material and financial resources.

Our products line includes:AAC,AAAC, ACSR, ACAR,Galvanized Steel Wire, Aluminium Clad Steel Wire,PVC wire, PVC/XLPE power cable, Aerial Bundled Cable, Medium Voltage Power Cable 2kV –46kV and High Voltage Power Cable.

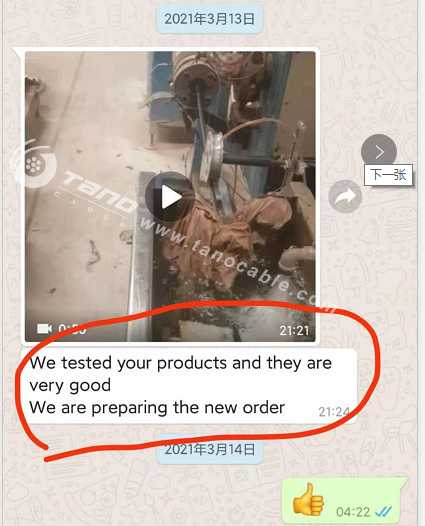

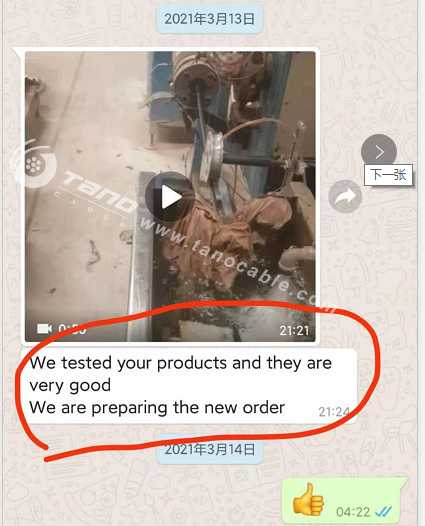

Our cables have been delivered to customers, they have tested the products and said that satisfacted at the result. Customer affirm our product and plan pruchasing again in next month. Below is screenshot of phone.

In the process of purchasing wires and cables, consumers should pay attention to the following items:

First, observe the appearance of the wire. The insulating (sheath) layer of qualified products is soft, tough and stretchable, and the surface layer is tight, smooth and without roughness. If the plastic wrapping the wire is easily peeled off, there is a problem of insufficient plastic strength.

Second, it depends on the cross section of the wire. The surface of the copper core or aluminum core of the qualified product should have metallic luster, and the black copper or white aluminum indicates that it has been oxidized.

Third, pay attention to checking the quality certificate when purchasing wires. If the quality of the wire is qualified, then the quality of the wire should also be inspected and there will be no major problems.

TANO CABLE always provides the qualified cable to customers. Our customer’s praise is our biggest motivation to insist on producing best quality cables. TANO CABLE is your best choice and looking forward to your inquiry and cooperation.

When you need purchasing cables for electrical applications and electric project.

Contact us now for a quote: https://www.tanocable.com/contact.html

Email :info@tanocable.com

1. Mark unqualified wires and cables. Marking is the main way for wires and cables to identify the basic information of products. According to the standard, the main content of the mark is: product model, specification, standard number, factory name, place of origin, etc. within a certain mark interval. When the mark is unqualified, it will cause The construction personnel's identification errors may cause electrical accidents in serious cases.

2. Wires and cables with unqualified structural dimensions. The main problem of the structure size is the thickness of the sheath and the insulation thickness. When the sheath and insulation thickness of the cable are not up to the standard, the electric resistance strength of the wire and cable will be seriously reduced, resulting in the shortening of the service life of the wire and cable, and in severe cases, the wire and cable may be damaged. Breakdown, the insulation (sheath) layer fails to provide normal protection, resulting in electrical short circuits and fires.

3. Wire and cable with qualified tensile strength and elongation of sheathed insulation before aging. The unqualified tensile strength and elongation of the insulating sheath before aging directly greatly shorten the working life of the wire and cable, and during construction or in a long-time energized environment with high temperature, the insulator is easily broken, resulting in a live conductor Exposed, there is a risk of electric shock short-circuit. The main reason for its disqualification is the use of recycled materials to reduce product costs, and the second is small enterprises that are not qualified for production.

4. Wires with unqualified conductor resistance. Conductor resistance is mainly an important indicator for assessing whether the conductor materials and cross-sections of wires and cables meet. When the conductor resistance exceeds the standard, the loss when the current passes through the line is increased, and the heating of the wire and cable is aggravated. The main reason for the unqualified conductor resistance is to reduce the cost of the copper material, which accounts for 80% of the raw material cost. In order to reduce the cost, either reduce the cross-sectional area of the conductor or use recycled copper with excessive impurities, which causes serious conductor resistance of the wire and cable. Exceeding the standard, in addition to easy to cause fire during use, it will also accelerate the aging of the insulating layer covering the wire.

When you use TANO CABLE’s products, you don’t worry about the problems of cable. We pay attention to quality of cables and reputation. As a leading and professional manufacturer, we are committed to providing customers and partners with the best integrated cable and wire solutions to save manpower, material and financial resources.

Our products line includes:AAC,AAAC, ACSR, ACAR,Galvanized Steel Wire, Aluminium Clad Steel Wire,PVC wire, PVC/XLPE power cable, Aerial Bundled Cable, Medium Voltage Power Cable 2kV –46kV and High Voltage Power Cable.

Our cables have been delivered to customers, they have tested the products and said that satisfacted at the result. Customer affirm our product and plan pruchasing again in next month. Below is screenshot of phone.

In the process of purchasing wires and cables, consumers should pay attention to the following items:

First, observe the appearance of the wire. The insulating (sheath) layer of qualified products is soft, tough and stretchable, and the surface layer is tight, smooth and without roughness. If the plastic wrapping the wire is easily peeled off, there is a problem of insufficient plastic strength.

Second, it depends on the cross section of the wire. The surface of the copper core or aluminum core of the qualified product should have metallic luster, and the black copper or white aluminum indicates that it has been oxidized.

Third, pay attention to checking the quality certificate when purchasing wires. If the quality of the wire is qualified, then the quality of the wire should also be inspected and there will be no major problems.

TANO CABLE always provides the qualified cable to customers. Our customer’s praise is our biggest motivation to insist on producing best quality cables. TANO CABLE is your best choice and looking forward to your inquiry and cooperation.

When you need purchasing cables for electrical applications and electric project.

Contact us now for a quote: https://www.tanocable.com/contact.html

Email :info@tanocable.com

Previous article:

Next article: