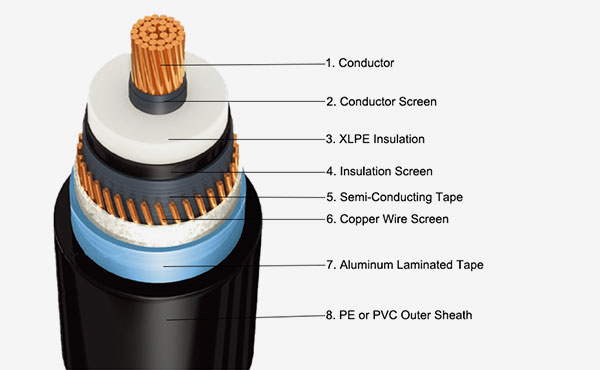

| 38/66 (72.5) kV with Corrugated Aluminum Sheath | ||||

| Continuous Current Ratings for Single Circuit (A) | ||||

| Cross Sectional Area (mm2) |

Direct Buried | Pipe Duct | In Air | |

| Trefoil | Flat (S=2D) |

|||

| 240 | 524 | 491 | 598 | 671 |

| 300 | 592 | 556 | 682 | 770 |

| 400 | 671 | 631 | 781 | 888 |

| 500 | 762 | 714 | 894 | 1025 |

| 630 | 878 | 808 | 1023 | 1187 |

| 800 | 965 | 928 | 1150 | 1355 |

| 1000 | 1119 | 1075 | 1361 | 1615 |

| 1200 | 1198 | 1146 | 1460 | 1745 |

| 1600 | 1352 | 1357 | 1654 | 2030 |

| 2000 | 1468 | 1475 | 1800 | 2273 |

| Conductor | Thickness of Conductor Screen (Approx.) |

Thickness of Insulation |

Thickness of Insulation Screen (Approx.) |

Thickness of Aluminum Sheath |

Thickness of Outer Sheath |

Outer Dia. of Cable (Approx.) |

Weight of Cable (Approx.) |

Max. DC Conductor Resistance at 20°C |

Capacitance | ||

| Cross Sectional Area |

Shape | Dia. | |||||||||

| mm2 | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | μF/km | |

| 240 | Compact Round Stranded |

18.1 | 1.0 | 11.0 | 1.0 | 1.6 | 3.5 | 69 | 5500 | 0.0754 | 0.20 |

| 300 | 20.4 | 1.0 | 11.0 | 1.0 | 1.6 | 3.5 | 72 | 6300 | 0.0601 | 0.21 | |

| 400 | 23.2 | 1.0 | 11.0 | 1.0 | 1.7 | 3.5 | 75 | 7200 | 0.0470 | 0.23 | |

| 500 | 26.3 | 1.0 | 11.0 | 1.0 | 1.8 | 4.0 | 79 | 8600 | 0.0366 | 0.25 | |

| 630 | 30.2 | 1.0 | 11.0 | 1.0 | 1.8 | 4.0 | 83 | 10100 | 0.0283 | 0.28 | |

| 800 | 34.0 | 1.0 | 11.0 | 1.0 | 1.9 | 4.0 | 87 | 12000 | 0.0221 | 0.30 | |

| 1000 | Segment Stranded (Miliken) |

38.7 | 1.0 | 11.0 | 1.0 | 2.0 | 4.0 | 92 | 14400 | 0.0176 | 0.33 |

| 1200 | 41.8 | 1.0 | 11.0 | 1.0 | 2.1 | 4.5 | 98 | 16700 | 0.0151 | 0.36 | |

| 1600 | 48.1 | 1.0 | 11.0 | 1.0 | 2.2 | 4.5 | 105 | 20900 | 0.0113 | 0.40 | |

| 2000 | 54.3 | 1.0 | 11.0 | 1.0 | 2.4 | 4.5 | 112 | 25400 | 0.0090 | 0.44 | |

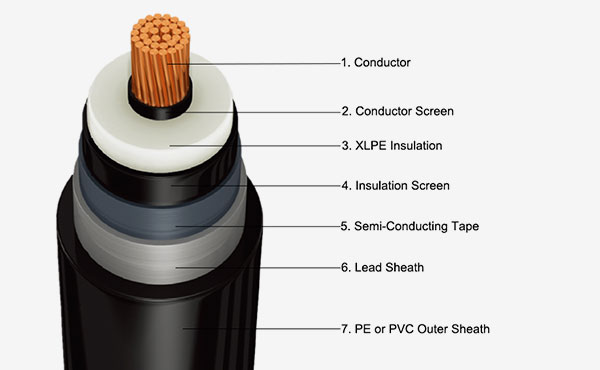

| 38/66 (72.5) kV with Lead Sheath | ||||

| Continuous Current Ratings for Single Circuit (A) | ||||

| Cross | Direct | Pipe Duct | In Air | |

| Sectional | Buried | |||

| Area (mm2) | Trefoil | Flat (S=2D) |

||

| 240 | 535 | 525 | 621 | 706 |

| 300 | 606 | 567 | 710 | 810 |

| 400 | 691 | 646 | 822 | 942 |

| 500 | 787 | 733 | 951 | 1098 |

| 630 | 898 | 833 | 1096 | 1274 |

| 800 | 1008 | 958 | 1243 | 1462 |

| 1000 | 1184 | 1121 | 1505 | 1759 |

| 1200 | 1282 | 1208 | 1648 | 1938 |

| 1600 | 1469 | 1434 | 1906 | 2282 |

| 2000 | 1626 | 1585 | 2130 | 2597 |

| Conductor | Thickness of Conductor Screen (Approx.) |

Thickness of Insulation |

Thickness of Insulation Screen (Approx.) |

Thickness of Lead Sheath |

Thickness of Outer Sheath |

Outer Dia. of Cable (Approx.) |

Weight of Cable (Approx.) |

Max. DC Conductor Resistance at 20°C |

Capacitance | ||

| Cross Sectional Area |

Shape | Dia. | |||||||||

| mm2 | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | μF/km | |

| 240 | Compact Round Stranded |

18.1 | 1.0 | 11.0 | 1.0 | 2.1 | 3.5 | 62 | 8100 | 0.0754 | 0.20 |

| 300 | 20.4 | 1.0 | 11.0 | 1.0 | 2.2 | 3.5 | 64 | 9100 | 0.0601 | 0.21 | |

| 400 | 23.2 | 1.0 | 11.0 | 1.0 | 2.3 | 3.5 | 67 | 10500 | 0.0470 | 0.23 | |

| 500 | 26.3 | 1.0 | 11.0 | 1.0 | 2.4 | 4.0 | 72 | 12500 | 0.0366 | 0.25 | |

| 630 | 30.2 | 1.0 | 11.0 | 1.0 | 2.4 | 4.0 | 76 | 14200 | 0.0283 | 0.28 | |

| 800 | 34.0 | 1.0 | 11.0 | 1.0 | 2.6 | 4.0 | 80 | 16900 | 0.0221 | 0.30 | |

| 1000 | Segment Stranded (Miliken) |

38.7 | 1.0 | 11.0 | 1.0 | 2.7 | 4.0 | 85 | 19900 | 0.0176 | 0.33 |

| 1200 | 41.8 | 1.0 | 11.0 | 1.0 | 2.8 | 4.5 | 91 | 23000 | 0.0151 | 0.36 | |

| 1600 | 48.1 | 1.0 | 11.0 | 1.0 | 3.0 | 4.5 | 97 | 28000 | 0.0113 | 0.40 | |

| 2000 | 54.3 | 1.0 | 11.0 | 1.0 | 3.2 | 4.5 | 104 | 33400 | 0.0090 | 0.44 | |

| 38/66 (72.5) kV with Aluminum Laminated Tape | ||||

| Continuous Current Ratings for Single Circuit (A) | ||||

| Cross | Direct | Pipe Duct | In Air | |

| Sectional | Buried | |||

| Area (mm2) | Trefoil | Flat (S=2D) |

||

| 240 | 530 | 483 | 606 | 692 |

| 300 | 599 | 544 | 693 | 795 |

| 400 | 683 | 616 | 802 | 925 |

| 500 | 780 | 729 | 929 | 1075 |

| 630 | 886 | 828 | 1066 | 1247 |

| 800 | 997 | 929 | 1210 | 1432 |

| 1000 | 1173 | 1087 | 1473 | 1728 |

| 1200 | 1270 | 1173 | 1611 | 1894 |

| 1600 | 1465 | 1375 | 1883 | 2245 |

| 2000 | 1627 | 1530 | 2111 | 2556 |

| Conductor | Thickness of Conductor Screen (Approx.) |

Thickness of Insulation |

Thickness of Insulation Screen (Approx.) |

Dia. & No. of Copper Wires |

Thickness of Outer Sheath |

Outer Dia. of Cable (Approx.) |

Weight of Cable (Approx.) |

Max. DC Conductor Resistance at 20°C |

Capacitance | ||

| Cross Sectional Area |

Shape | Dia. | |||||||||

| mm2 | mm | mm | mm | mm | mm | mm | mm | kg/km | Ω/km | μF/km | |

| 240 | Compact Round Stranded |

18.1 | 1.0 | 11.0 | 1.0 | 1.2×40 | 3.5 | 58 | 4400 | 0.0754 | 0.20 |

| 300 | 20.4 | 1.0 | 11.0 | 1.0 | 1.2×40 | 3.5 | 60 | 5100 | 0.0601 | 0.21 | |

| 400 | 23.2 | 1.0 | 11.0 | 1.0 | 1.2×40 | 3.5 | 63 | 5900 | 0.0470 | 0.23 | |

| 500 | 26.3 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.0 | 66 | 7200 | 0.0366 | 0.25 | |

| 630 | 30.2 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.0 | 71 | 8600 | 0.0283 | 0.28 | |

| 800 | 34.0 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.0 | 75 | 10400 | 0.0221 | 0.30 | |

| 1000 | Segment Stranded (Miliken) |

38.7 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.0 | 80 | 12700 | 0.0176 | 0.33 |

| 1200 | 41.8 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.5 | 85 | 14700 | 0.0151 | 0.36 | |

| 1600 | 48.1 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.5 | 91 | 18700 | 0.0113 | 0.40 | |

| 2000 | 54.3 | 1.0 | 11.0 | 1.0 | 1.2×40 | 4.5 | 97 | 22700 | 0.0090 | 0.44 | |