SALES SERVICE

We attach great importance to service, because we firmly believe that the timely and efficient service is the best way to win our client’s trust and final satisfaction. It is our mission to provide most suitable solution in shortest time in every stage of pre-sales, in-sales, and after-sales.

01

PRE-SALES

1) We always do internet promotion and participate international exhibition to make us more easier to be contacted by our client.

2) We always keep perfect our official website to enhance client’s browsing experience.

3) We always keep updating our social platforms, such as Facebook, Linkedin, YouTube, Twitter, Instagram and so on, and always keep on line for chatting tools, such as SKYPE, WHATSAPP, WECHAT, QQ and so on, to keep close contact with our client as friends.

4) We always keep standby in 24 hours a day, 7days a week, even in holidays. We always give prompt response to our client’s contact, and quotation can be sent within 24 hours.

5) We always keep close communication with our client to understand the needs clearly to provide most suitable commercial solution and technical solution.

6) We always try our best to provide documents as client’s requirement, such as technical drawing, technical data sheet, sales performance list, type test report, etc.

7) We provide free sample, however, the express fee should be taken on by client.

2) We always keep perfect our official website to enhance client’s browsing experience.

3) We always keep updating our social platforms, such as Facebook, Linkedin, YouTube, Twitter, Instagram and so on, and always keep on line for chatting tools, such as SKYPE, WHATSAPP, WECHAT, QQ and so on, to keep close contact with our client as friends.

4) We always keep standby in 24 hours a day, 7days a week, even in holidays. We always give prompt response to our client’s contact, and quotation can be sent within 24 hours.

5) We always keep close communication with our client to understand the needs clearly to provide most suitable commercial solution and technical solution.

6) We always try our best to provide documents as client’s requirement, such as technical drawing, technical data sheet, sales performance list, type test report, etc.

7) We provide free sample, however, the express fee should be taken on by client.

02

IN-SALES

1) We make order evaluation, and clarify every detail with client to avoid any mistake, and then sign official contact with client. Our production will follow the signed contract strictly.

2) For supporting our client, absolutely, the flexible commercial conditions, faster lead time, will be provided.

3) We always send production plan and report the production progress timely, so that the client can handle the whole situation.

4) We always send inspection documents according to client’s requirement.

5) We can provide third-party inspection service and give support to any third-party assigned by the client.

6) We can recommend forwarder t, and inquiry most competitive freight for client.

7) We always send packing and delivery report to client.

8) We always follow and update the shipping situation, and provide customs clearance documents to assist client pick up the cargoes.

2) For supporting our client, absolutely, the flexible commercial conditions, faster lead time, will be provided.

3) We always send production plan and report the production progress timely, so that the client can handle the whole situation.

4) We always send inspection documents according to client’s requirement.

5) We can provide third-party inspection service and give support to any third-party assigned by the client.

6) We can recommend forwarder t, and inquiry most competitive freight for client.

7) We always send packing and delivery report to client.

8) We always follow and update the shipping situation, and provide customs clearance documents to assist client pick up the cargoes.

03

AFTER-SALES

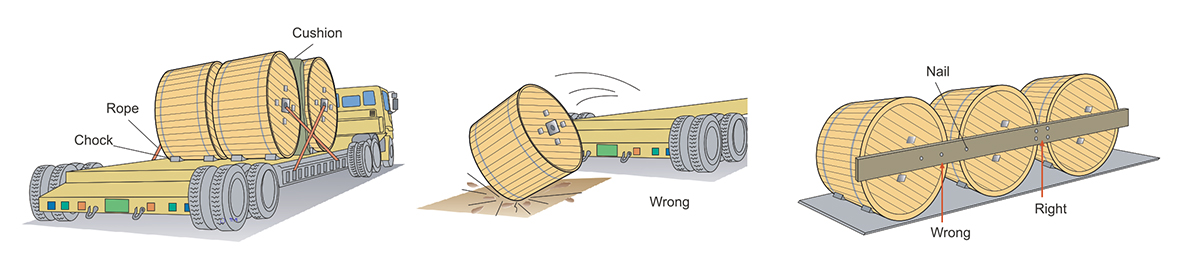

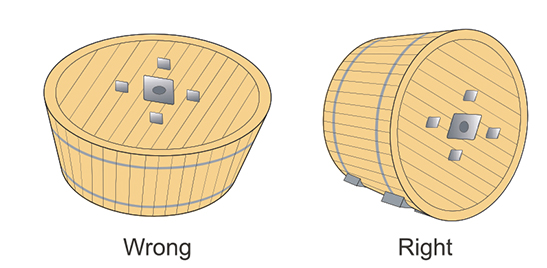

1) We always send installation manual to client.

2) We always ask about the cable laying situation, and give prompt solution in case of any problem.

3) We provide longer quality guarantee period, normally, it is 18 months against the date of B/L, and 12months after installation. In case any default(except improper laying and man-made damage) caused by our quality problem will be found during the warranty period, we guarantee that we undertake to substitute immediately the defaulted cables if time will be sufficient or in a contrary case we authorize you since now to repair or buy the new cables from other competitors and in both cases we will charge for all related expanses .

4) We always collect suggestion from our client to make improvement. Anyway, we promise that we will give biggest support to support, to work, to grow together with our client.

2) We always ask about the cable laying situation, and give prompt solution in case of any problem.

3) We provide longer quality guarantee period, normally, it is 18 months against the date of B/L, and 12months after installation. In case any default(except improper laying and man-made damage) caused by our quality problem will be found during the warranty period, we guarantee that we undertake to substitute immediately the defaulted cables if time will be sufficient or in a contrary case we authorize you since now to repair or buy the new cables from other competitors and in both cases we will charge for all related expanses .

4) We always collect suggestion from our client to make improvement. Anyway, we promise that we will give biggest support to support, to work, to grow together with our client.