01

Jun

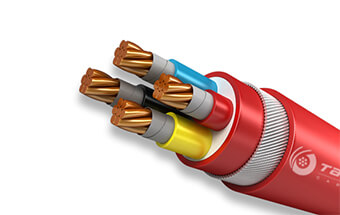

Five-step production of a good cable

Share:

Need strict raw material purchasing, production, transportation, sales, etc. The whole process of quality control, raw material procurement examined strictly, to supplier's product, than the quality, price, service, goods than five.Take the raw material quality and cheap, and is equipped with ten thousand tons of oxygen free copper rod production line, wire drawing factory, plastics factory, the rubber refining mill factory, from the early start for continuous production ability, provides the guarantee for the production of high quality and low price products.

2. Production link

Use wire and cable manufacturing process characteristics of special production equipment in the industry, so as to adapt to the structure, performance requirements, cable products meet the requirements of large length of continuous and high-speed production as soon as possible, thus formed the cable manufacture special equipment series.Such as extruder series, wire drawing machine series, winch series, winding charter series.

3. Inspection department

In the process of production, production line staff income is directly linked to product quality, production workshop, the head of the job evaluation directly linked to the quality, each process has a strict operating rules and quality responsibility.system.quality department, we should use the advanced equipment, scientific testing means for production line down time product inspection, inspector sampling, measuring after signed by the team leader for the record and inform the line production personnel, nonconforming product line, personnel on duty can't leave.Random spot check for each batch of products not in stock.The technicians of the company's inspection department use professional instruments to inspect the finished products according to the strict rules of quality control.

4. Warehousing acceptance

Keeper also wants when receiving the product into the Treasury is the product of wire diameter, length, sampling observation of sheath and insulation, adhesion, such as found not up to national standard, can refuse to put in storage and demand quality department recheck.

5. Sales organization inspection

In line with the principle of not letting the consumer suffer loss, before the commodity enters into circulation, the sales organization carries on the inspection to the goods arrival, discovers the production disqualification or the packing damage to return to the factory in time.